Tool box design build welding, Ace Engineering

|

AboutAce toolboxes started when a local contractor came to us to make them a set of Aluminium toolboxes to fit onto one of their service utes. One set turned into two then as they got around the district we fielded more and more enquiries and began to build all sizes and shapes of tool boxes for a range of industries. Development

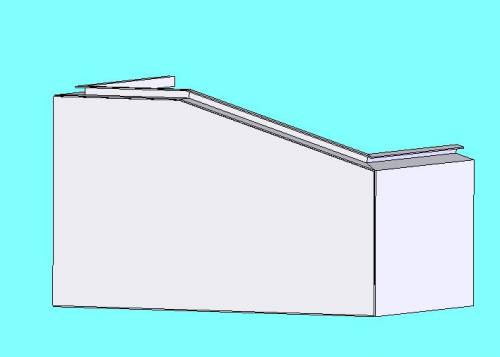

After a while we began to develop a standardized range of sizes to suit most purposes. With the aid of our 3D design software we were able to maximize material efficiency and minimize build times. CAD also allowed us to fine tune tolerances and enable to rapidly change/customize boxes for specific requirements. Design

Our boxes are designed with a double return lip around all sides of the opening in itself creating a full waterproof seal, rubber trim can be added to this to make an airtight seal. Construction

The main body of the box is folded in one piece with each end fully welded in using the latest digital pulse welding machines and fully qualified tradesmen. Locks

Shelving

We can custom build around chest toolboxes and specialized tools/equipment. So we leave it up to you the customer to tell us your ideal layout. |